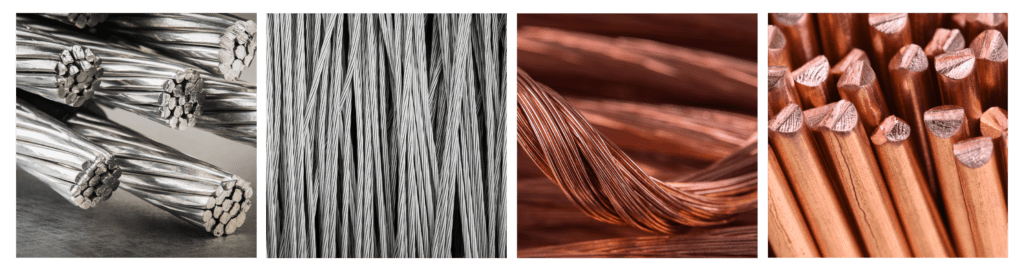

Over the years, new technology and new research has vastly improved the safety and efficiency of electricity in homes. One of these technologies is the type of wire that we use to power your home. Since the mid-60s, aluminum wire has become a popular choice, but special considerations need to be made in its use nowadays.

What is Aluminum Wiring?

During the 60s and 70s, the price of copper wiring went through the roof.

Most homeowners couldn’t afford to shell out the extra cash to have their new houses set up with copper. The alternative was a less expensive conductor: aluminum.

Although the quality of aluminum wasn’t quite as high as copper, its price point was an attractive selling feature. In order to increase conductivity, manufacturers sold aluminum wire that was slightly thicker than its copper counterparts. This was intended to make up the difference, as it were.

What Issues Are Related to Aluminum Wiring?

Most homes built during that time period were wired with aluminum wiring. Many of the homeowners discovered, however, some disconcerting side effects. Flickering lights, warm cover plates, and burned insulation on the wiring caused a lot of concern.

A little bit of digging revealed that the main danger was in the connections. Aluminum wiring would expand three times more than copper wiring, creating a lot of heat in a small space. It was a fire hazard just waiting in the walls when not maintained properly.

How Can Those Issues be Overcome?

Further research determined that if the problem was at the connection points, then special connectors needed to be made in order to offset the expansion. Aluminum wiring and the receptacles are still in use today.

As a general rule, keep an eye out for anything marked with AL-CU or CU-AL. Since aluminum wiring is a reality for many homeowners with older homes, it is important to maintain regular inspections to ensure that everything is running smoothly.

If you own a home from the 60s or 70s, there is a good chance that it has been wired with aluminum. In these cases, it’s important not to risk DIY maintenance. Bring in the professionals so that we can keep your home to standard, and your family safe.

At 4-Star Electric we’ve been providing best-in-class electrician services throughout the Calgary area since 1989, so we’ve seen plenty of aluminum wiring and are well-aware of the issues it can cause. We’re standing by to give you the best solutions for your home and budget, give us a call today.

Aluminum vs. Copper

Copper is quickly replacing aluminum wiring in most residential and commercial applications. Below is a quick comparison table highlighting the key differences between them.

Again, keep in mind that while aluminum wiring is still used in some applications, particularly in power grids, its use in residential buildings has decreased due to safety concerns, as stated above. Copper remains the preferred choice for household wiring due to its higher conductivity, safety, and durability.

| Aspect | Aluminum Wiring | Copper Wiring |

| Conductivity | Good. | Excellent, industry standard. |

| Cost | Cheaper option. | More expensive option. |

| Weight | Lighter option. | Heavier option. |

| Durability | Prone to oxidation, corrosion. | Highly durable and corrosion resistant. |

| Flexibility | More malleable. | More rigid. |

| Heat Expansion | Expands easier, can lead to loose connections. | Less expansion, maintains connections. |

| Uses | Used in larger power transmission lines. | Commonly used in residential and commercial buildings. |

| Safety Concerns | High risk of fire and overheating in improper installations. | Safer and more reliable, industry standard. |

| Maintenance | Requires more inspection and maintenance, especially as it ages. | Easy to maintain, inspect semi-regularly along with the rest of your electrical system. |

| Installation | Special connectors, tools and techniques needed. | Universal, straightforward installation. |

FAQ About Aluminum Wiring

Does 4-Star Electric Replace Aluminum Wiring?

We can replace aluminum wiring in certain applications, but if this is for a residential property it wouldn’t be our first choice. At 4-Star Electric our team is here to restore your home’s electrical with safer options . Whether it’s restoring wiring in certain rooms, upgrading your outlets, or rewiring your entire home, we can help!

Is it necessary to completely replace aluminum wiring in a home?

Complete replacement of aluminum wiring with copper wiring is one solution, but it can be expensive and disruptive. An alternative is to use special connectors , which are designed to safely connect aluminum wires to copper wires or devices.

These methods reduce the risk of overheating without the need to replace all the wiring. However, any modification or repair should be done by the licensed electricians at 4-Star Electric, due to our experience with all things aluminum wiring.

Can aluminum wiring be safe if properly installed and maintained?

Yes, aluminum wiring can be safe if it is properly installed and maintained. This includes using the correct connectors, ensuring that connections are tight and secure, and regularly inspecting the wiring for signs of wear, overheating, or corrosion.

It’s also important to use switches, outlets, and fixtures that are compatible with aluminum wiring. Regular professional inspections by our experienced team are also recommended to maintain safety.

How much does requiring my home cost?

The cost of rewiring an entire home is based on the total length of wire being replaced and the number of outlets in your home. Unless your outlets are rated for both copper and aluminum wiring, they will also need to be replaced to be compatible with your new wiring.

Why Choose 4-Star Electric

We don’t consider it a job well done until you’re 100% SATISFIED! We’ll always ask for your approval before taking payment for any electrical rewiring or restoration service.

We also stand behind our work, and all aluminum wiring restorations are guaranteed for 3 years! If the wiring we restore or replace fails within 3 years of your service date, we’ll redo the work at no extra cost.

Call our team of experienced professionals today!