Many different materials go into building a home, and as time goes by, technology and standard practices are always evolving. When it comes to electrical wiring, different conductors perform on different levels. In today’s new home construction, copper is king when it comes to electrical wiring.

Aluminum wiring can provide a path for electrical current to operate but this doesn’t mean it’s the best choice. For the most part, aluminum electrical wiring is safe. But keeping a home that has aluminum wiring secure requires careful electrical workmanship when changes and upgrades are made to your electrical system.

Learn when aluminum wiring was used in homes in Alberta and how to spot this outdated wiring in an older home. In this blog, we’ll discuss the potential hazards of aluminum wiring that has been neglected or worked on without proper standards.

If your home is currently wired with aluminum, it may be time to upgrade to copper or have it properly maintained. Our trusted electricians at 4-Star Electric can help! We’ve been upgrading homeowner’s electrical wiring for decades.

Give us a call, set up an appointment, and take the first steps in making your home safer and your electrical wiring more reliable.

Why Was Aluminum Used to Wire Homes?

During the late 1960s and 1970s, Canadian homes were often wired with aluminum as the main conductor of choice. This provided a cost-effective and lightweight means of distributing electricity throughout the home.

But as we’ve come to learn, improvements can always be made to the quality of material being installed in your home. Following this period, copper became the preferred metal for residential and commercial electrical wiring.

How to Identify Aluminum Wiring

Apart from knowing the year in which your home was built (typically between 1965 and 1978 in Canada), aluminum wiring can present itself in a few different ways:

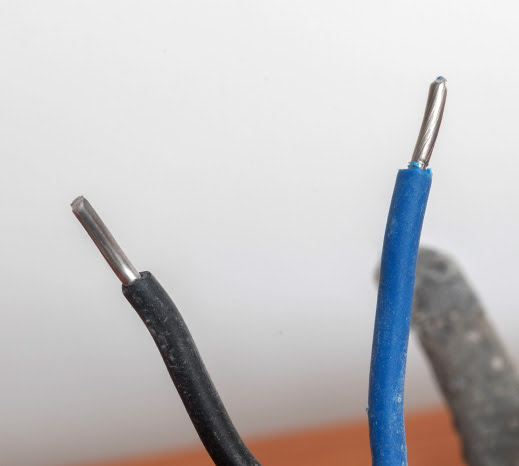

- Aluminum wiring has specific colouring that helps identify the conductor. Aluminum is a silver colour, while copper is more yellow/gold/rust-coloured.

- Your wire jackets (outer layer of wires) are labelled with “aluminum” or “AL”

- CO/ALR markings are visible on wiring device-binding terminals, standing for “copper/aluminum revised”.

What Are the Disadvantages of Aluminum Wiring?

Aluminum wiring can be hazardous for a variety of reasons, including the fact that it can easily separate from the screws on electrical outlets, switches, or lights. This can result in a faulty connection and the wire heating up. The metal may oxidize as a result of this excessive heat, which could result in an electrical fire in the worst cases.

Apart from that, aluminum as a conducting material possesses properties that have made it obsolete when wiring a home. The disadvantages of aluminum wiring include:

- When aluminum is exposed to moisture and comes into contact with certain other metals, it will experience galvanic corrosion.

- When compared to copper wiring, aluminum wiring is more easily oxidized. Aluminum oxide, which is created when aluminum is oxidized, is less conductive than copper oxide.

- When compared to copper, aluminum has a relatively high resistance to electrical flow. As a result, when given the same amperage, aluminum conductors must be larger in diameter than copper wires.

- As the temperature changes, aluminum expands and contracts dramatically, causing the connections between the wiring and the device to gradually lose their effectiveness and durability.

- Aluminum is extremely sensitive to compression. For example, if a screw-on aluminum wiring is overtightened, the wire will distort in the same way even after the tightening is undone. This can result in a sloppy connection as well as an increase in electrical resistance.

What Can be Done to Repair Aluminum Wiring Problems?

In a perfect world, the best course of action once you find aluminum wiring in your home is to replace all of it. However, this can become costly depending on the size of your project and not mandatory.

One option involves connecting existing aluminum wiring to newer, safer, copper wiring that is commonly used today. This could be as simple as using the proper aluminum connectors. Or it can be a more involved solution, such as updating certain sections of your home in different phases.

In most situations, a short piece of copper wire, properly attached to an existing piece of aluminum wiring with the appropriate connector and a deox agent is an acceptable repair, when completed by a licensed electrician.

CO/ALR connections are devices that may be used to provide a solution as well. They connect copper and aluminum properly, but mainly for temporary purposes. They can not be used for things such as lighting fixtures and permanent appliance wiring. But CO/ALR connectors are specifically designed for installations with existing aluminum wiring where receptacles and light switches may be required.

Does Upgrading Your Home’s Wiring Seem Complicated?

Any electrical upgrade, including rewiring your home from aluminum wiring to copper wiring, is something that should only be done by someone with knowledge and experience. If improving your home’s electrical safety seems like a daunting task, just know that 4-Star Electric is here to help.

Aluminum wiring is safe when it’s inspected regularly and handled by a qualified electrician for modifications. 4-Star’s licensed electricians are qualified to rewire all types of electrical systems and will help make sure your home is protected from the potential risks of outdated aluminum wiring.

If you know you’ve got aluminum wiring throughout your home, give us a call to set up a consultation. We’ll review your home’s electrical and recommend the best steps for staying safe and getting the most out of your home’s energy consumption.